Product Description

.Horizontal peeler centrifuge is a continuous and intermittent operation centrifuge. Both automatic control and manual control systems are available in the horizontal peeler centrifuge. The process of feeding, separating, washing, dewatering, discharging and reproducing filter cloth during the operation of centrifuge are generally completed in the full speed state, the single cycle time is short, the amount of treatment is large, and the dry filter slag and good washing effect can be obtained.

Horizontal peeler centrifuge is widely used in chemical, food, light industry, pharmaceutical, starch and other industries.

Horizontal peeler centrifuge is suitable for the suspension containing coarse, medium and fine particles, such as ammonium carbonate, PVC, wood modified starch and so on. As a professional potato, sweet potato and cassava starch processing machine manufacturer, our peeler centrifuge also professional used in the starch production, mainly for starch slurry dehydration.

Our machine of horizontal peeler centrifuge is solid-liquid separation equipment which adopts continuous operation and

intermittent discharging. It regulates speed by frequency convertor, breaking system adopts dynamic braking. Through such procedures as product level detection, speed inspection, shaft temperature and vibration monitoring, the whole separation process is automatic circulative work(including feeding, dehydration, washing, discharging and etc.) Also manual operation mode is available which can be changed over from full-automation mode by customer’s will.

Specification

|

Model

|

Length (mm)

|

Width (mm)

|

Height (mm)

|

Power (kw)

|

Weight (kg)

|

|

GK800

|

1700

|

1625

|

1555

|

30

|

5000

|

|

GK800M

|

2495

|

1490

|

1550

|

30

|

6500

|

|

GK1050

|

2215

|

2300

|

2200

|

37

|

6500

|

|

GK1200

|

2340

|

2400

|

2475

|

45

|

8000

|

|

GK1250

|

2300

|

2950

|

2615

|

45

|

9000

|

|

GK1250A

|

3250

|

2600

|

2520

|

55

|

10000

|

|

GK1600

|

4090

|

3200

|

3080

|

90

|

15000

|

Working Principle

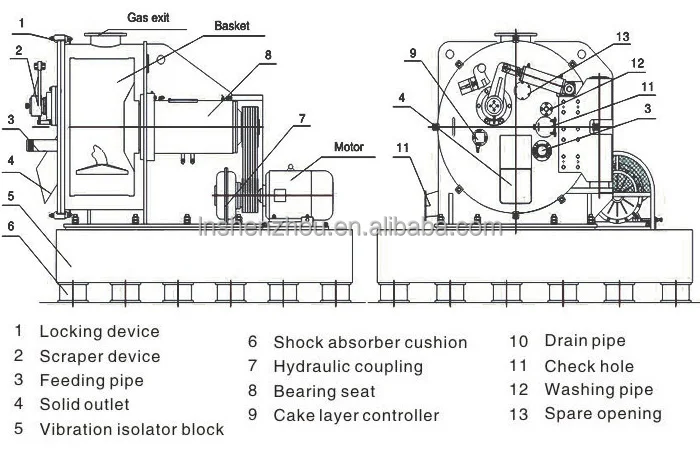

The working principle of horizontal peeler centrifuge:

After the motor drives the drum to reach full speed, the feed valve opens automatically. The suspension is moved into the drum with the feed pipe. The liquid phase is centrifuged through the filter and the drum wall filter hole, and the solid material is cut into the drum. After the motor drives the drum to reach full speed, the feed valve opens automatically. The suspension is moved into the drum with the feed pipe. The liquid phase is centrifuged through the filter and the drum wall filter hole, and the solid material is cut into the drum.

Main configurations of horizontal peeler centrifuge:

1. PLC control for long-distance monitoring: touch-screen dialogue for easy maintenance and operation.

2. Action elements with automatic electric-pneumatic/hydraulic control.

3. Two discharging modes available: chute discharging featuring simple construction, and discharging through scroll conveyor and scraper featuring high catching rate of solid cake and effectively prevent blocking.

Features

Main features of horizontal peeler centrifuge:

1. Automatic operation without care can achieve man-machine conversation, convenient operation and maintenance.

2. The whole process of feeding, primary filtration, washing, fine filtration and unloading is monitored

3. Independent electrical control box, remote control can be realized.

4. Safety protection: includes rotation speed monitoring, over-vibration protection, cover opening protection, motor overload and overheat protection, dual control with both mechanical and electrical for scraper.

5. Fully enclosed structure, silicone rubber.

6. The motor and centrifuge main engine are installed as a whole to facilitate users and it can reduce the space occupied by the machine.

7. The contact parts of centrifuge and separation medium are made of stainless steel, which improves the corrosion resistance and hygienic requirements of the machine.

8. Using of siphon system and the production efficiency is high

9. Equipped with backwashing device, it can wash the outer side of the centrifuge drum and the inner side of the shell, so as to achieve the cleanliness requirement of the process.

Applications:

*Applications:

Model GK centrifuge is the filter equipment characterized with continuous running, scraper discharging and intermittenent

operation, applicable to the separation of the suspension liquid containing medium sized granules or fine granules(0.01mm- 5mm).It can also be used for the separating of the suspension liquid containing short fibers(with the fiber length less than 4mm), with the concentration of the suspension liquid being 10%-60%. With hydraulic and electric joint control mode adopted, this series of centrifuges are capable of high degree of automization, with such working processes as by means of PLC for full automatic control.

The horizontal scraper discharging centrifuge has good adaptability to the material to be processed and thus can be widely used in such industrial fields as chemical, light industry, food, pharmacy, etc. for the separating of over 100 kinds of substances including ammonia sulphate, sodium sulphate, anthracene, boric acid, starch, pesticide, synthetic resin, sodium cyanide, potassium chloride, sodium bicarbonate, etc.

2.Descriptions of model GK1050 horizontal scraper discharging peeler industrial centrifuge machine

Company Profile

Liaoyang Shenzhou Machinery Equipment Co., Ltd is a professional for supplier of pharmaceutical and chemical machine in China.We have a well-experienced team and a professional design institute,With rich experiences in pharmaceutical machinery and equipment including packing machine, centrifuge, falling film evaporator, distillation,mixer, tablet press machine, suppository production line,dryer,capsule filling machine ,capsule and so on.Our products are exported to many countries and areas, such as the USA, Korea, India, Indonesia,Thailand, Vietnam,Japan, Denmark,Romania, Bulgaria,Russia,South Africa, and so onAt the same time,our product with best prices and good quality,welcome to Shenzhou!