Disc centrifuge Centrifuge used to wvo centrifuge disc

Model No.︰DHZ

Brand Name︰LYSZ

Country of Origin︰China

Unit Price︰US $ 18500 / pc

Minimum Order︰1 pc

Product Description

Product Description

Disc centrifuge Centrifuge used to separate water and particles from mineral oil

automatic discharging separator is special equipment for oil and fat refining, it has the traits as high rotating speed, operating stability, completely sealed up of the inlet and outlet system, lower noist and fine separating affection. Centripetal pump system designed by our professional designer has the traits as stability outlet pressure, large regulating sphere and operating easily.

Also this series separator has professional automatic domination case with safety protection device, advanced automatic vibrating testing instrument can view vibrating testing instrument can view vibrating number at any time. We can make separating and discharing to the best affection from regulate separting parameter directly at the screen.

Solids-retaining centrifuges for separating water and particles from mineral oils such as fuel and lubricating oils, compressor oils, hydraulic, running in and metal working oils designed to handle oil flows from 4 to 38 gallons per minute. Water and particle free oil is essential for the quality of most processes. Complete range of separators

Feature:

Features

* High speed centrifugation to remove oil grease and sludge impurities

* Strong emulsification ability

* Low energy consumption,saves money

* Full automation possible with PLC automatic control panel.

* Centrifugal separation requiring no filter media.

* High reliability drive train system backed by delivery of over 1,000 units a year.

* Bowl design with superior separation performance and with good response to discharge loads.

* Pilot valve regulates total/partial discharge of solids.

* Super partial discharger (option) minimizes liquid loss and maximizes thickening of solid

* Fraction for discharge.

* Vibration-proof design realizes long working life.

Working Principle

How does Disc Separator work?

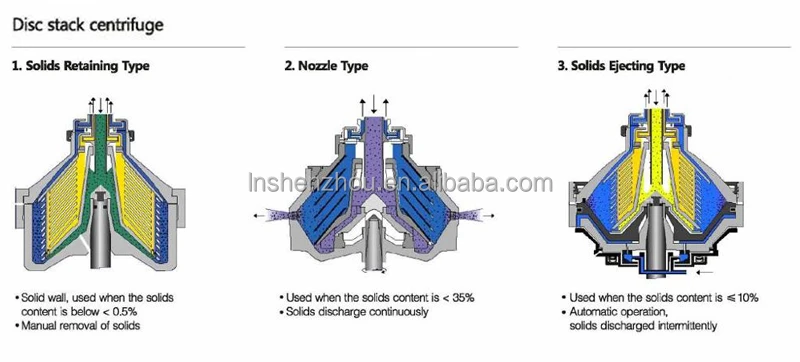

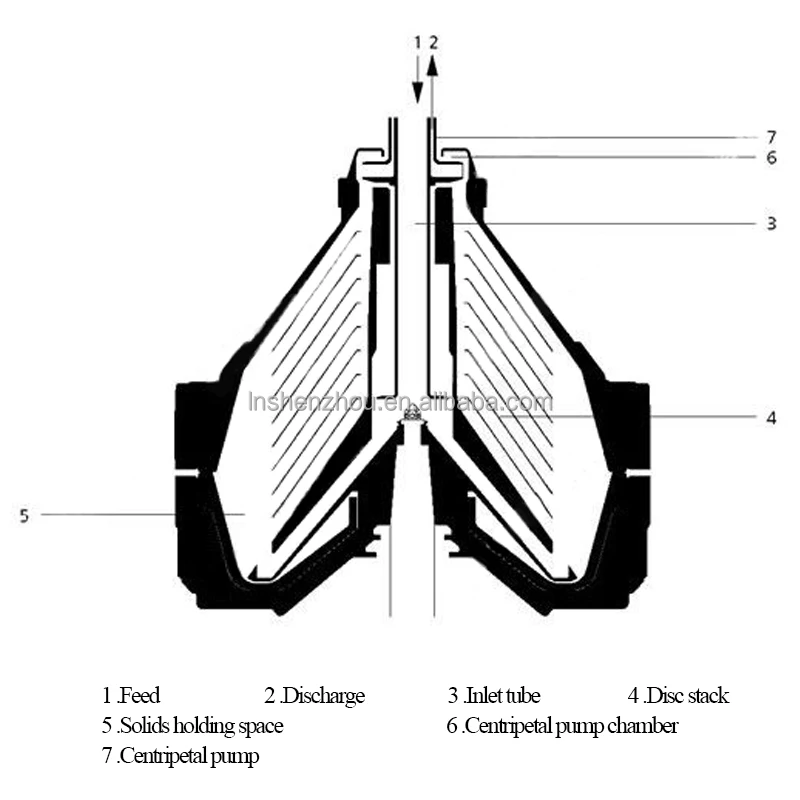

The disc separator is in vertical structure. The drum is mounted on the upper end of the vertical axis, which is driven by a motor and rotates at a high speed. There is a set of disc - shaped parts that are stacked together in the drum, with a small gap among them. When the suspension (or emulsion), which is pumped into the drum by feeding tube located in the center of the drum, pass through the gap between the discs, solid particles (or droplets) would settle down to form sediment (or liquid layer) on the disc by centrifuge force, and then the sediment slid along the surface of the disc and separated from the disc to accumulate in the largest diameter of the drum. At last, the separated liquid discharged from the outlet. The disc is utilized to shorten the settling distance of solid particles or droplets, enlarge the settlement area of the drum, and improve the production capacity of the separator. The solids accumulated in the drum are removed from the drum by manual after the machine stop, or out of the drum in the case of a dregs machine without stopping.

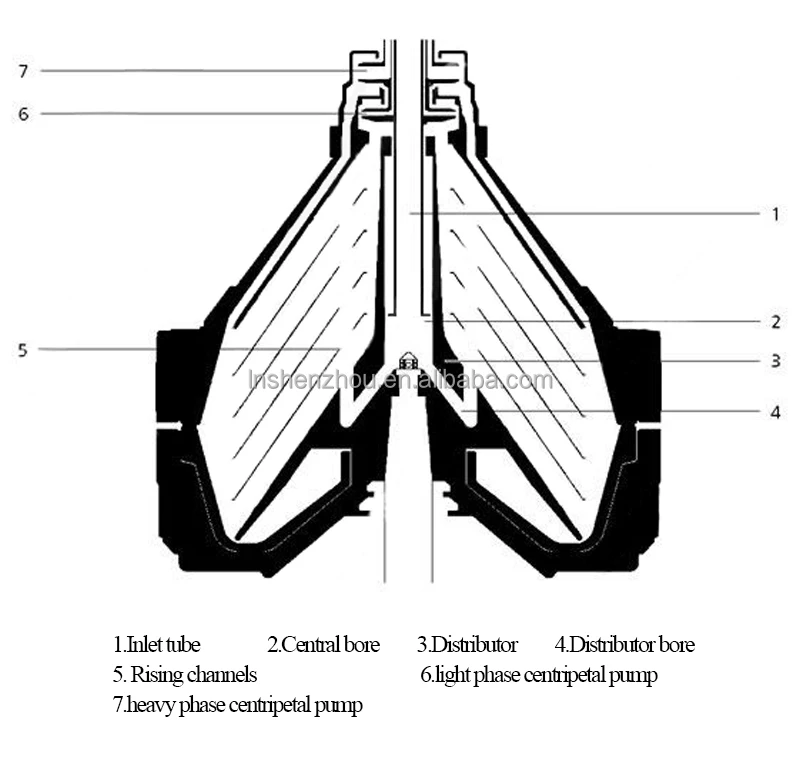

Main Structure

Powerful Motor provide power through the thermal coupling to drive drum in high-speed rotating around the main axis. And the liquid material is carried by feeding pipe located in the upper center into the bottom of the drum, and then led in the porthole below the disc and driven to the drum wall. Under centrifugal force, solid- liquid-liquid do the below motion to complete thorough separation:solid phrase, which is heavier than liquid, would sink into the inner wall of the drum for sediment formation; light liquid flow in centripetal pump, and be discharged by liquid outlet; The heavy liquid tends to the drum wall along the cone inside the disc, and then flows upward through through the heavy liquid concentric pump to be discharge from the outlet.

Due to the double-conical design of the inner cavity of the drum, it can compress the slag and increase its concentration.

Besides, some nozzles is mounted around the drum to spray slurry sediment, whose number and aperture are determined on the properties of the suspension, the degree of concentration and the amount of treatment.

In order to improve the slag concentration, recovery device is configured with this disc separator to the discharged sediment for reuse. For the solid concentration of the slag can be increased by 5~20 times than that of the feeding materials.

The processing capacity of the separator is up to 30t/h, which is suitable for suspension with solid phrase in diameter of 0.1~100 microns and concentration less than 10% (maximum to 25%).

Disc Oil Separator Application:

Treatment of lube

Treatment of oil, water and solid substances

Treatment of drilling slurry

Water removal of crude oil

Treatment of cooling lubricant

Treatment and water removal of lubricant and hydraulic oil

Treatment of waste emulsion and waste oil

Treatment of aging oil

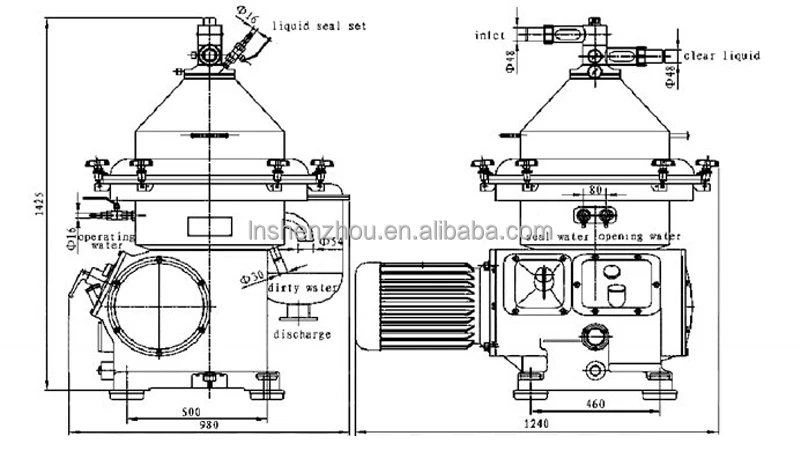

Specification

|

Model |

Treatment capacity (L/H) |

Inlet Pressure (Mpa) |

Outlet pressure (Mpa) |

Motor power (Kw) |

Weight (Kg) |

Outline dimension (mm) |

|

DHZ360 |

1200-2500 |

0.05 |

0.1-0.25 |

7.5 |

1280 |

1500*1150*1500 |

|

DHZ470 |

2500-7000 |

0.05 |

0.1-0.25 |

15 |

1880 |

1800*1200*1800 |

|

DHZ550A |

5000-10000 |

0.05 |

0.1-0.25 |

18.5 |

2200 |

1850*1550*2050 |

|

DHZ550E |

6000-15000 |

0.05 |

0.1-0.25 |

22 |

2200 |

1850*1550*2050 |

|

DHZ700 |

15000-30000 |

0.1 |

0.2 |

30 |

3300 |

2100*1650*2300 |

|

DRZ360 |

1200-2500 |

0.05 |

0.1-0.25 |

5.5 |

750 |

1250*1050*1500 |

|

DRZ400A |

2000-6000 |

0.05 |

0.1-0.3 |

7.5 |

1150 |

1300*900*1450 |

|

DRZ400E |

4000-7500 |

0.05 |

0.1-0.3 |

7.5 |

1300 |

1300*900*1500 |

|

DRZ550 |

6000-18000 |

0.05 |

0.1-0.3 |

22 |

2200 |

1620*1300*2200 |

Company Profile

Liaoyang Shenzhou Machinery Equipment Co., Ltd is a professional for supplier of pharmaceutical and chemical machine in China.We have a well-experienced team and a professional design institute,With rich experiences in pharmaceutical machinery and equipment including packing machine, centrifuge, falling film evaporator, distillation,mixer, tablet press machine, suppository production line,dryer,capsule filling machine ,capsule and so on.Our products are exported to many countries and areas, such as the USA, Korea, India, Indonesia,Thailand, Vietnam,Japan, Denmark,Romania, Bulgaria,Russia,South Africa, and so onAt the same time,our product with best prices and good quality,welcome to Shenzhou!

Packing & Delivery

wooden case

Payment Terms︰ TT

Product Image